Beef Cattle Artificial Insemination School Offers Hands-On Training at Busby Farm

Office of Communications and Marketing

Young Hall

820 Chestnut Street

Jefferson City, MO 65101

An attendee tries to find the cervix opening using the artificial insemination simulator.

An attendee tries to find the cervix opening using the artificial insemination simulator.

Lincoln University of Missouri (LU) hosted a Beef Cattle Artificial Insemination (AI) School at its Alan T. Busby Farm, giving participants an opportunity to learn and practice modern reproductive techniques used in cattle breeding.

Bruce Shanks, a former LU employee who continues to collaborate on the AI clinic, led the event. Lincoln University staff assisted with the training, including Michael Reinkemeyer, assistant farm manager at George Washington Carver Farm; Eric Groose, farm manager; and Chris Boeckmann, farm superintendent.

Artificial insemination allows producers to improve herd genetics without the cost of maintaining a bull. During the workshop, Shanks walked participants through each step of the multi-part process, from anatomy lessons to hands-on practice with the cattle.

Attendees first learned in a classroom setting about the structure of a cow’s reproductive system. They also learned three key principles for successful insemination: the cows must be in heat, the semen sample must be viable and properly handled and insemination must be performed with the proper technique.

The group also discussed fixed-time and split-time AI methods. Fixed-time AI uses hormonal protocols, often aided by a Controlled Internal Drug Release (CIDR) device, to synchronize the cows’ estrous cycles, allowing insemination at a set time without heat detection.

Split-time AI involves multiple insemination attempts to increase success rates.

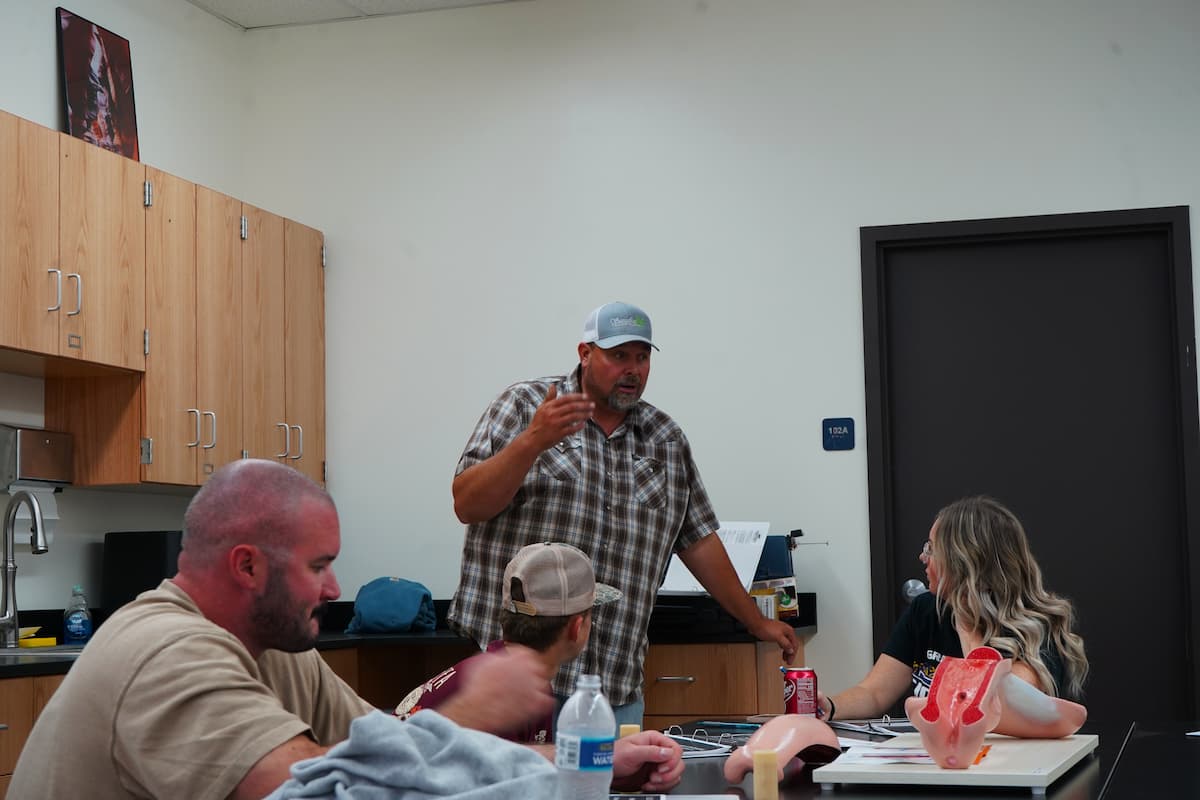

Bruce Shanks teaches attendees the importance of proper artificial insemination procedures.

Bruce Shanks teaches attendees the importance of proper artificial insemination procedures.

Following the classroom sessions, participants moved to the barn for hands-on practice, where reproductive systems from real cattle — a cow and a heifer — were on display. Before participants began live practice, Shanks offered one piece of practical advice: “Always have lots of paper towels.”

Participants practiced locating the cervix using a box-mounted replica before attempting the procedure on live cows. Shanks noted the cows used for training were not in heat, which made the process more challenging.

“The first step is finding the cervix, which is gonna feel like a tennis ball but bristly,” Shanks said. “It feels kinda like a turkey neck.”

Cows have three “annular rings” in the cervix, which feel rough and can make the procedure difficult. Finding and threading the insemination gun through these rings are often the two most challenging parts of AI.

One participant asked why semen can’t be deposited the same way a bull does it.

“We’re dealing with less volume,” Shanks explained. “The bull’s got a ton of volume, and you only need one to make it.”

Groose added that artificial insemination is not always successful. “A couple cows we’d AI’d four years in a row never took to the AI, but they took the bull breed every time,” Groose said.

He suggested participants breeding just one or two cows should purchase at least two semen straws to ensure a viable backup during heat.

Participant Gage Payne traveled from Russellville after seeing the event advertised on Facebook. “I’ve been wanting to learn how to do this for a while — get access to a better-quality bull, better genetics for a cheaper price,” Payne said.

As participants wrapped up the day’s lessons, many left with a deeper appreciation for both the science and patience behind successful breeding. The program not only built technical skills but also fostered confidence among producers seeking to improve herd genetics and efficiency on their own farms.

For information on the next training, contact Chris Boeckmann at BoeckmannC@lincolnu.edu.